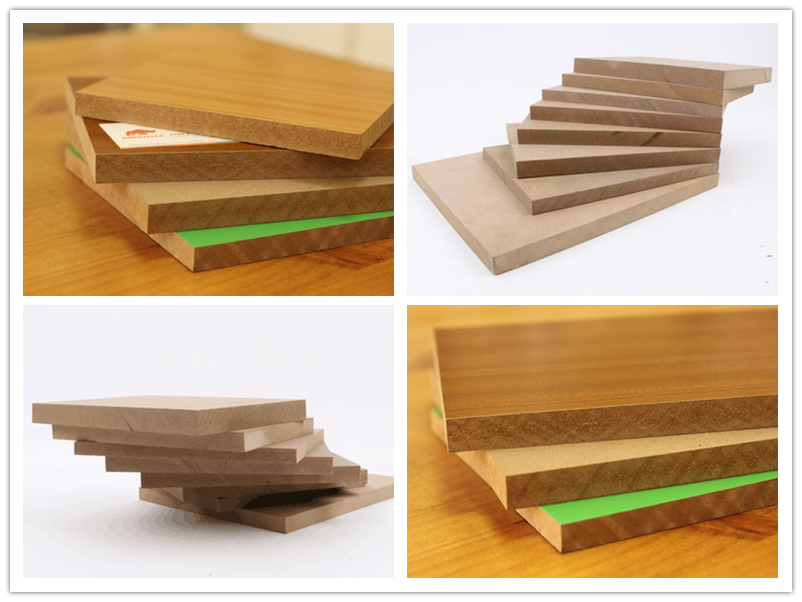

Melamine Faced MDF

Medium-density fibreboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming panels by applying high temperature and pressure. MDF is generally denser than plywood. It is made up of separated fibres, but can be used as a building material similar in application to plywood. It is stronger and much denser than particle board

Description

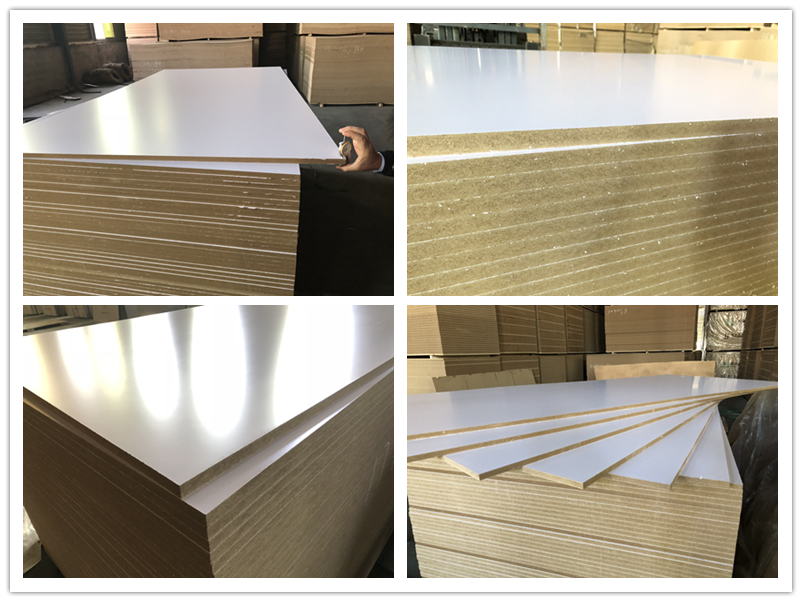

Melamine Faced MDF

Medium-density fibreboard (MDF) is an engineered wood product made by breaking down hardwood or softwood residuals into wood fibres, often in a defibrator, combining it with wax and a resin binder, and forming panels by applying high temperature and pressure. MDF is generally denser than plywood. It is made up of separated fibres, but can be used as a building material similar in application to plywood. It is stronger and much denser than particle board

ADVANTAGES

1. Approaches the natural timber.

2. The structure is even and the density is moderate.

3. It can process into various kinds of forms and various kinds design model results.

4. Be widely used to make display cabinets, furniture, wall panels, storage units etc.

5. Suitable for sorts of surface treatment with melamine paper presents wood grain etc.

| Testing Items | Unit | Performance Indicators |

| Density | Kg /m² | 550-650 |

| Water Content | % | 6-12 |

| THickness Tolerance | mm | ±0.3 |

| Degree Of Deformation | % | ≤0.50 |

| Bonding Strength | MPA | ≥0.70 |

| Peel Strength (Waterproofing Quality) | / | Boiled eight hours under 63℃,no abscission layer |

| Thickness Expansion Rate(24H) | % | ≤5 |

| MOR | MPA | ≥30 |

| Emission Of Formaldehyde | mg/L | E1≤1.5 E2≤5 E0≤0.5 |

Email:

Email:  Whatsapp:

Whatsapp: