Description

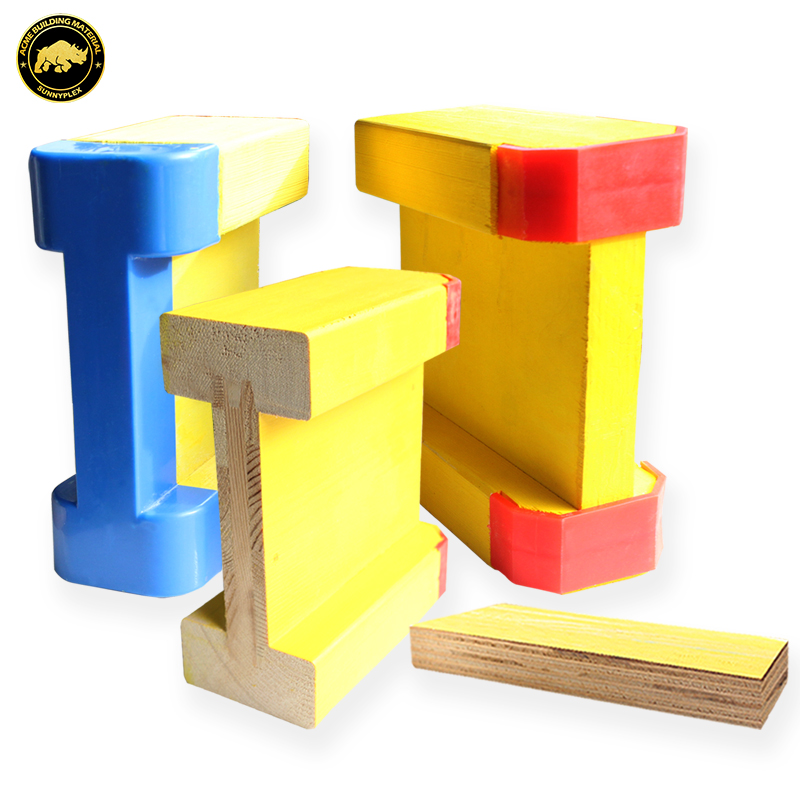

Plastic Formwork H20 Timber Beam Formwork Construction H20 Beam

H20 Beam

SUNNYPLEX

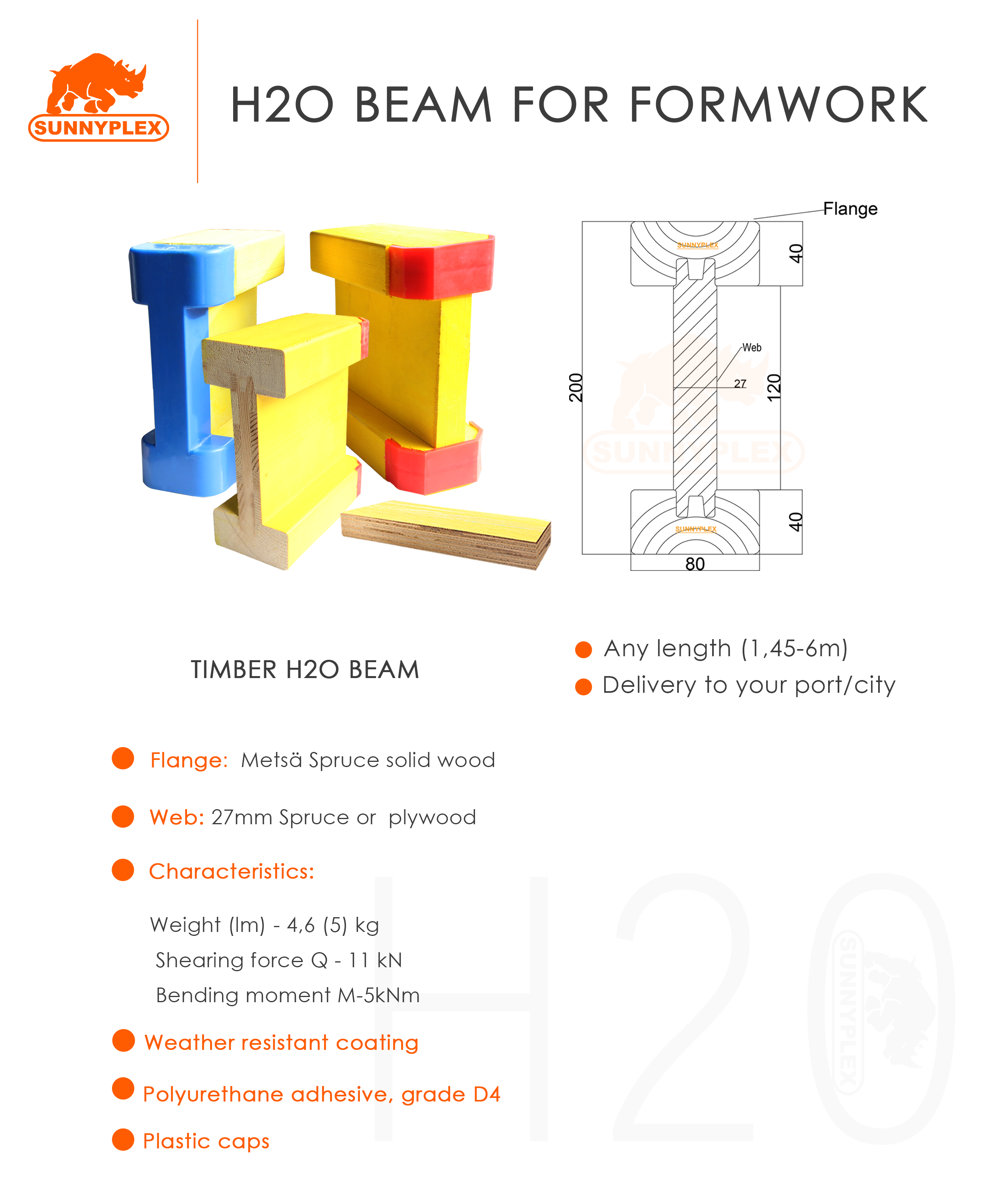

Dimensions & Tolerances

Technical Specifications

The values of the section modulus and the geometrical moment of inertia apply to new or used concrete formwork beams. An analogously increased factor of safety needs to be added for severely worn beams.

Beam

Wooden beam for formwork, consisting of an upper and lower wing and featuring a central section consisting of three layers. The union is designed as a notched and glued joint.

Heads

Highest-quality fir wood, calibrated with level edges and featuring finger joints along their length.

Webs

of plywood or a three-layer board with a thickness of 27mm

Joint

Notched, finger-type joint between core and wings, throughout their length. High-frequency, high-strength gluing.

Anti-humidity treatment

Protective paintwork throughout the beam.

Advantages

Strength and Safety

Dimensional stability and recovery capacity after application of load. High load capacity throughout their length. Protection against humidity, knocks and splintering.

Lightness

Easy handling and quick assembly. Minimum weight.

Economical

Can be used many times. Good ratio between price and uses. Easy storage.

Adaptability

Ideal for use with formwork board. Supports can be placed at any point. Can be used in any kind of formwork.

Standard sizes

Length: 5900, 4900, 4500, 3900, 3600, 3300, 2900, 2650, 2450, 1950 mm

Height: 200 mm

Width: 80 mm

Weight

Per linear meter: 5 kg ±0.2

Email:

Email:  Whatsapp:

Whatsapp: